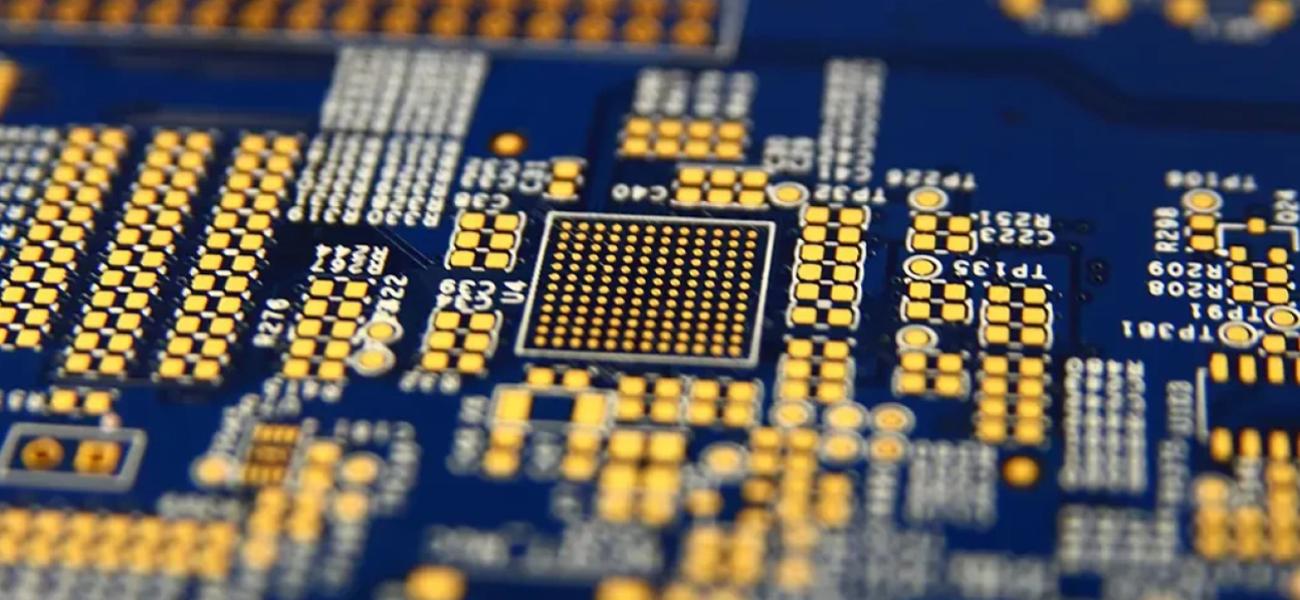

PCB division, more than 100 years experience in PCB manufacturing

Cistelaier S.p.A. in Italy together with Techci Rhône-Alpes in France and EPN Electroprint GmbH are the three Printed Circuit Boards manufacturing companies belonging to the Finmasi Group PCB Division.

Cistelaier, established in 1998 merging the two industrial entities, Cistel S.r.l., established in Genoa in 1976 and Laier S.r.l., established in Modena in 1986, manufactures prototypes, small, medium and large series of a very wide range of printed circuit boards: double-sided, multilayer, rigid-flex, rigid and rigid-flex multilayer HDI PCBs and PCBs manufactured with special materials.

Given all its accreditations, produces all kind of PCBs for all market sectors with a very wide range of materials and almost all finishes.

Techci has been established in 1983 in Saint Genix Sur Guiers, France, their capabilities in PCB manufacturing in terms of technology and services are very similar to Cistelaier’ capabilities.It is mostly focused in Aerospace, Defense and Civil avionic fields.

EPN has been established in 1988 in Neustadt, in Turingia Region in Germany and mainly devoted to production of PCBs for the industrial field.

Vision, Mission and Business Model

Our vision is to be leading manufacturer offering Global Services and Local Support to consumers mainly, but not only, on the European market.

Our mission is to continue developing capabilities, services and know-how to offer our customers the widest range of PCBs in terms of technologies and services, from double-sided PCBs to HDI rigid and HDI rigid-flex PCBs of high and very-high technology level, in small, mid and high volumes, even with quick turnaround delivery, manufactured in our own plants in Europe.

We complete our offer for high quantities through our fully controlled long standing sourcing-partnerships with highly qualified Asian manufacturers.

Our business model is to supply PCBs to our customers from the first prototype batch, with quick turn around service upon request, to the serial production. We reserve our capacity and capability to manage QTA service only for our real partners who can share our business model thus contributing to build long-term partnerships that represent the basis to grant our continuity and growth.

Accreditation and Standards

What makes the PCB Division unique, is to be certified to produce, not only for the industrial sector through ISO9001:2015 but also for critical sectors such as:

Aerospace & Defence: UNI EN 9100:2016 (Cistelaier & Techci)

Avionic: NADCAP (Techci)

Automotive: IATF:2016 (Cistelaier)

Medical: ISO 13485 (Cistelaier)

Railway: ISO/TS 22163 (Cistelaier & Techci)

Products are manufactured according to the following standards and specific control plans are agreed with customers if needed:

IPC-A-600, class 2, 3 or class 3DS(A)

IPC 6012 (Rigid), IPC 6013 (Rigid-Flex), IPC 6016 (HDI) and IPC 6018 (Microwave)

MIL-P-55110 (Rigid) and MIL-P-50884 (Rigid-Flex)

ESA-ECSS - Q – ST – 70 – 10C / 11C / 12C

ESA-ECSS - Q – ST – 70 – 60C

Cistelaier, Techci and EPN are also IPC Members and several employees are QualifiedIPC Trainers and IPCSpecialists. Thanks to their know-how and accreditations and to their flexible service they have been able to become technological partners of customers performing in almost all market sectors.

Products

Cistelaier and Techci produce and sell all kinds of PCBs: double-sided PCBs, rigid multilayer boards up to 40 layers, rigid-flex boards up to 12 flex layers and HDI multilayer rigid and rigid-flex boards.

Cistelaier and Techci validated their processes to produce with more than 100 different base materials so as to deliver PCBs for all possible applications.

They produce with standard-performance materials and with high-performance materials (i.e. Hi Tg, Alogen Free, Hi-speed, epoxy and polyimidic resin materials, copper/invar/copper, HI frequency materials Teflon and not Teflon based, thick copper materials).

EPN produces PCBs of what we call standard technology from single-sided PCBs to 10 layers PCBs even with quick-turn delivery service.

The PCB Division could deliver PCBs with:

lines and spaces down to 75 microns width

length / width combinations of the panel up to 860 mm x 470 mm

thickness of the panel up to 5.5 mm

copper thickness up to 500 microns

copper coins and bas bars insertion

mixed materials build up

all finishes: ENIG, ENEPIG, chemical Tin, HAL Lead and Lead free, chemical Silver, OSP, electrolytic Nichel – Gold (Hard & Soft), tin-lead hot oil reflow

all colours of solder mask: green, red, blue, black, white, grey and specific RAL on request.

Services

Factories and Organizations of the PCB Division have been designed and implemented in order to be able to provide quick turnaround (QTA) service: this enables customers to get prototypes with short lead times so to improve their time-to-market and business performances.

All information related to products design coming from our customers are systematically verified in order to identify any risk factors through DFM, DFT and FMEA analysis.

Through our own mechanical and chemical LABs we can deliver all possible analysis results requested by PPAP Reports, CoC Reports or FAIR (First Article Inspection Reports) or by customized qualification processes for PCB conformity validation.

Our people, highly skilled in PCB design and manufacturing, are ready to support our partners at any time.